|

| January 27, 2015 | Volume 11 Issue 04 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

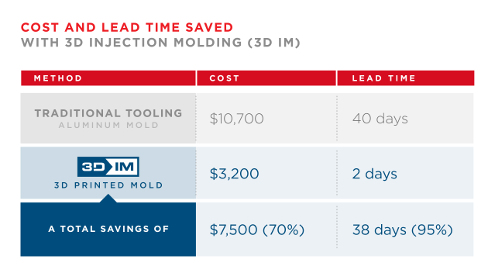

Make injection molds 95% faster, 70% cheaper

Stratasys PolyJet-based 3D-printed mold tools are able to withstand the heat and pressures of injection-molding machines.

Stratasys, a leading global provider of 3D-printing and additive manufacturing solutions, is collaborating with design and product development company Worrell to accelerate medical device development through the use of 3D-printed injection molding (which Worrell refers to as "3D IM").

Since 3D printing injection mold tools for medical devices, the company is producing injection-molded prototypes using final production materials in 95% less time and at 70% less cost compared with traditional aluminum molds.

Medical device manufacturers traditionally face two main obstacles in getting medical devices to market: tooling costs and the FDA regulatory process. Traditional tooling is both costly and time consuming, as new molds must be created every time a prototype is refined before manufacturing. To reduce potential iteration risks and tooling costs, Worrell uses Stratasys PolyJet-based 3D printers to create injection-molding tools and then inject the same materials that will be used in a finished medical device, creating higher-fidelity prototypes.

3D-printed injection molds can efficiently produce medical device prototypes in the final material, in this case, polycarbonate.

"We were recently approached by medical device start-up MedTG to design and engineer a dual-flow needleless blood collection system that reduced the need for multiple injections, thereby increasing patient comfort and hospital efficiency. Utilizing 3D-printed injection molds to prototype the device, we were able to reduce the costs associated with traditional tooling by approximately 70%, as well as cutting times by 95%," says Kai Worrell, CEO at Worrell.

"Using 3D-printed injection molds, we are able to create a prototype for a fraction of the cost and in a matter of days compared to the eight-week lead time associated with traditional tooling processes," says Worrell. "This revolutionary manufacturing process enabled by Stratasys PolyJet technology is now an integral part of our product development cycle, allowing us to provide better prototypes for care providers, while saving our clients considerable time and money."

Stratasys says the 3DP IM molds work best with resins processed with melt temperatures below 300 C. The number of parts expected is between 5 and 100, where typically the number is between 20 and 50 parts depending on the part size, geometry, and injected material.

In a bid to promote the significant cost savings of 3D-printed injection molds for medical device manufacturers, as well as the huge reductions in product development cycles, Stratasys and Worrell plan to jointly attend international tradeshows and host a series of workshops to educate the medical industry on the innovative process and its radical impact on manufacturing.

Stratasys' Objet500 Connex 3D Printer takes its place in the traditional manufacturing floor at Worrell.

"We have recognized a significant under-utilization of the 3D-printed injection molding process in medical device development, and we're working with Worrell to help fill this gap," says Nadav Sella, Senior Manager of Manufacturing Tools at Stratasys. "Worrell is a leading design firm with the expertise and infrastructure necessary to integrate injection molding and 3D printing within the product development cycle. In an industry where products have the potential to save lives, we want to use this collaboration to demonstrate how medical device manufacturers can bring their products to market significantly faster than ever before."

Source: Stratasys

Published January 2015

Rate this article

View our terms of use and privacy policy